Protein A Resin Reduction Achieved With Process Transfer From Batch To Resolute® BioSMB

Sanofi sought to reduce the operating costs associated with existing purification steps, particularly those involving high resin costs. Regulatory concerns were to be addressed by evaluating the consistency of product quality during process transfer and scale-up. Additionally, the feasibility of extended purifications at production scale would be determined by testing the robustness of the Resolute® BioSMB system.

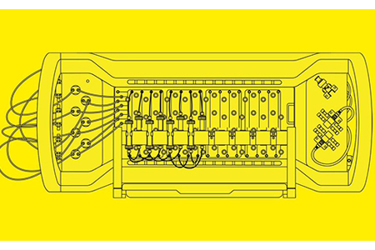

This study aimed to explore the advantages of multi-column chromatography as well as its application in a perfusion-based process. Key decision factors regarding technology selection included resin savings and the capability of continuous chromatography to operate for lengthy process times. The focus of the study was to transfer an existing batch chromatography process to a multi-column format and then scale it up to a continuous perfusion run. This involved a 50 L single-use perfusion bioreactor, where maintaining aseptic conditions and flow path robustness were crucial to achieving a target run time of 10 days, ultimately processing approximately 800 L of feedstock.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Biosimilar Development? Subscribe today.